A Guide to Electromechanical Assemblies

At Precision Manufacturing Company, Inc. (PMCI), we are a premier provider of electromechanical assemblies. Combining electrical circuitry with mechanical parts, these elements play a critical role in electrical and electronic systems across a wide range of industries, including aerospace, communications, military, power generation, and more. They can range from simple to highly complex, all of which should be designed and constructed carefully to ensure both good functionality and manufacturability.

Below, our experts have put together a guide to electromechanical assemblies. We cover what they are, what types are available, and what industries and applications they are used in.

What Are Electromechanical Assemblies?

The term “electromechanical assembly” can refer to anything from wire and cable subassemblies to full system assemblies known as box builds. In all of them, electrical and mechanical components and subassemblies work as a unit to perform a mechanical operation.

The components and subassemblies integrated into an electromechanical assembly vary depending on the part in which it will be installed and the application in which it will be used. They can include cable and wire assemblies, DIN rails, power supplies, programmable logic controllers (PLCs), printed circuit boards (PCBs), sensors, switches, and safety mechanisms.

During the assembly process, skilled electromechanical assembly specialists follow highly detailed blueprints to integrate the electrical circuitry with the mechanical elements. These specialists must be skilled in several aspects of electrical system fabrication, including through-hole mounting schemes, surface mounting techniques, soldering, and circuit layout. In addition to requiring an in-depth understanding of each electrical and mechanical component being used, the assembly process involves the handling of small and sometimes delicate mechanical components with exceptional precision, coordination, and focus.

Types of Electromechanical Assemblies

Generally, electromechanical assemblies are designed and built to perform a specific operation. Some of the most commonly manufactured include:

Switch and Sensor Assemblies

Two essential elements of electronic systems are switch assemblies and sensor assemblies, which differ in the function they provide and the components used in their construction. Switch assemblies are typically used to connect or disconnect a power supply to electrical components, while sensor assemblies are designed to convert stimuli, such as sound, heat, light, or motion, into electrical signals.

Switch assemblies generally consist of the following components:

- Contacts for controlling the flow of electrical current to the switch

- Wiring harness for holding the switch in place and providing a site for electricity to enter or exit the switch body

- Switching mechanism—usually a toggle device or pushbutton—for controlling the operation of the device

While sensor assemblies typically include:

- Sensing elements for detecting physical properties (temperature, pressure, radiation, etc.), motion, or proximity

- Housings for protecting the sensing elements

- Transmitters for transmitting the data gathered about the targeted property

- Connection heads for allowing the connection of the sensor wires to the transmitter

Panel Assemblies

Some electromechanical assemblies are integrated into panels. They typically serve as a method of controlling the distribution of electrical power into connected circuits. The process of creating these assemblies can involve:

- Positioning each component in the correct location on the back panel

- Punching or sawing holes for components

- Drilling holes for mounting hardware

- Wiring the panel

DIN Rail Assemblies

DIN rails—also known as mounting rails—are used to mount other components within an electromechanical assembly. They must be configured according to the components and subassemblies.

Power Supply Assemblies

A power supply provides electrical power to at least one electric load by converting a current to the correct format and voltage required to power it. Power supplies can be designed as either standalone devices or incorporated into appliances. General components of a power supply assembly include:

- Housing for protecting the other components

- Transformer for modifying the incoming voltage

- Rectifier for converting incoming power from AC to DC

- Filter for smoothing out waves in the DC output after rectification

- Regulator for reducing ripple voltages left by the filter

Transformer Assemblies

Transformers are designed to transfer electrical energy between two or more electrical circuits. They work by increasing or decreasing the voltage level according to the requirements of the application. Transformer assemblies generally include:

- Laminated core

- Primary and secondary windings

- Insulating materials

- Application-specific tanks and accessories (oil conservator, breather, cooling tubes, etc.)

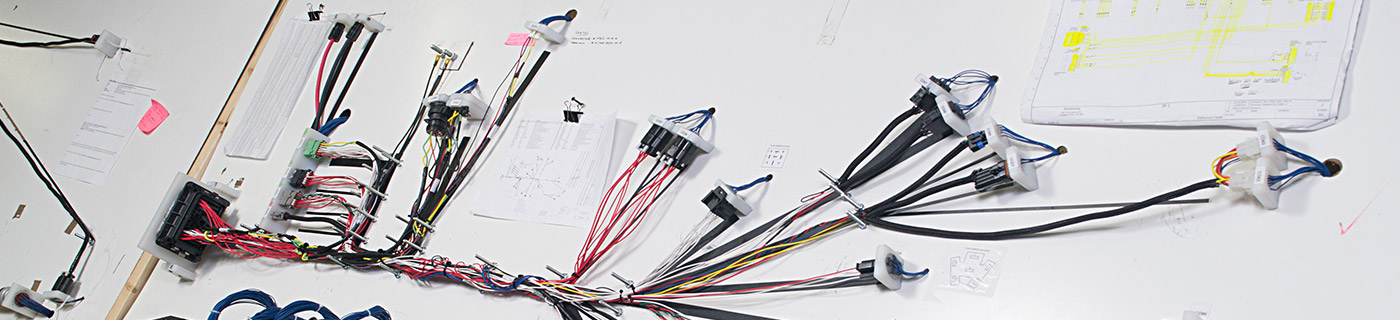

Cable and Harness Assemblies

Cable and harness assemblies consist of cables or wires that transmit electrical power or signals. Typical components include:

- Wires and cables to carry the power or signals

- Connectors to connect the cables and wires to each other and the electrical/electronic device

- Fuses to prevent damage caused by power surges

- Relays to turn the power on and off in high-amperage circuits

- Insulators to protect the components from touching each other and from the environment

- Ties to keep the wire harness fixed to the device or system

Industrial Applications of Electromechanical Assemblies

Electromechanical assemblies are found in a variety of electrical and electronic devices and systems, such as computer interfaces, displays, control systems, fan and blower systems, and power distribution networks. Some of the industries that regularly rely on them for their operations include:

- Aerospace: The aerospace industry relies on reliable, compact, and high-precision electromechanical assemblies with custom-designed layouts to accommodate unique features of different types of aircraft systems. Examples of electromechanical assemblies commonly used in aircraft include high-power connectors, junction boxes, power boxes, switch panels, and lighted cockpit panels.

- Automotive: Electromechanical assemblies used in the automotive industry are carefully designed to deliver high reliability and long operating life while providing the design flexibility necessary to meet various automotive system requirements. Common automotive electromechanical assemblies include speed sensors, temperature sensors, switching mechanisms, and relays.

- Agricultural: Agricultural equipment, such as tractors, sprayers, and combines, rely on switches, sensors, and other custom-designed electromechanical assemblies to operate effectively and efficiently.

- Heavy equipment: Heavy equipment and vehicles depend on robust custom cable assemblies, box builds, wire harnesses, and other assemblies to perform reliably in harsh environments.

- Military: Military-grade electromechanical assemblies support the sophisticated and interconnected nature of electronic military devices, vehicles, computer systems, and weapons while tolerating the extreme environments encountered in the industry. Electromechanical devices used in such applications include everything from rugged wire and cable harnesses to complex panel assemblies.

- Fire protection: High-performance electromechanical assemblies are a critical element of fire protection and suppression systems in hospitals, institutions, and other public and private spaces. Made from high-quality fire-rated materials, these assemblies help power everything from stairwell pressurization and smoke extraction fans to emergency generators and fire alarm systems.

Contact the Experts at PMCI Today

Given the critical function electromechanical assemblies perform in various industries and applications, it is essential to ensure it is designed and constructed properly. That’s why it is important to partner with an electromechanical assembly solutions provider with extensive experience and expertise. They can deliver electromechanical assemblies that offer reliability and durability in the intended application.

Looking for a partner for your electromechanical assembly needs? Turn to the experts at PMCI! We are a leading manufacturer of electromechanical assemblies that is certified to work across a wide range of industries. Whether you require a simple or highly complex assembly that complies with ISO 9001, IPC/WHMA A620, or other industry standards, our team will work one-on-one with you from design through testing to ensure you receive a high-quality, custom-tailored solution that fully meets your specifications.

For additional information on our electromechanical assembly capabilities, contact us today. To discuss your requirements with one of our team members, request a quote today.