Wire Harness Assemblies & Services

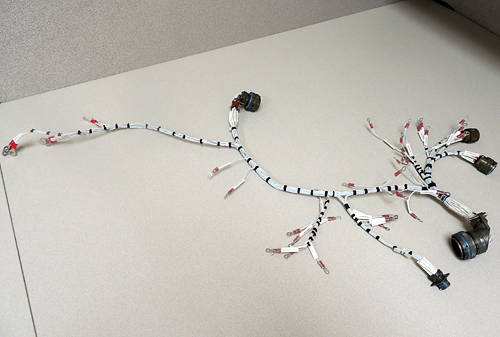

Wire harnesses transmit signals or electrical power in wide range of equipment, tools and vehicles which includes industries such as appliances, heavy equipment, medical equipment, defense weapons, and electronics. They’re made from groupings of cables, wires, and subassemblies. At their most basic, wire harnesses are constructed from three components, wires, terminals, and connectors, but they can become highly complex to handle multiple branches, safety features, and termination points.

Custom wire harnesses are the core of electronic applications. Manufacturers must build precise wire harness designs to ensure their products run efficiently and reliably.

Wire Harness Design and Manufacturing Process

Every wire harness needs to match the geometric and electrical requirements of the device or appliance for which it’s used. Wire harnesses typically are entirely separate pieces from the large manufactured components that house them. This brings a number of benefits, which include:

- Simple manufacturing processes by creating wiring for drop-in installation

- Easy disconnecting and current analysis for troubleshooting, disassembly, and part repair

- Simple installation processes with wire harnesses that include all of a product’s wires, cables, and subassemblies with quick connect/disconnects.

Each wire and terminal can be configured to match the exact length, dimensions, and layout of the main product it is connecting to. Wires can also be colored and labeled to streamline installation and maintenance.

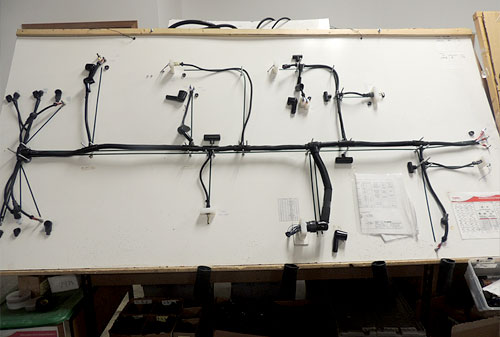

The manufacturing process starts with design and schematic development. It then moves to prototyping. Finally it goes into production. Operators assemble wire harnesses on drawn out test boards which confirms precisely measured wire lengths. The board also confirms that the designed terminal and connector housings that suit the application is being used, and that cable ties and coverings are added for easy organization and transport.

Although automation plays an important role in all manufacturing processes, the complexity of the end product means that many sub-steps of assembly process must be done by hand. Wire harness cable assembly is a multifaceted process. The main steps of this process include:

- Installation on the wires, terminals, and connectors on the build board

- Installation of specialty components such as relays, diodes, and resistors.

- Installation of cable ties, tapes, and wraps for internal organization

- Wire cutting and crimping for reliable terminal connection points

Applications and PMCI’s Specifications

Almost all electronic devices and appliances require wire harnesses to transmit electricity and signals. Wire harnesses simplify manufacturing and maintenance processes in residential, commercial, and industrial contexts. Common applications for wire harnesses include:

- Washing machines, dryers, refrigerators, and other household appliances

- Consumer and commercial electronics

- Automotive equipment

- Commercial and industrial machinery

- Medical equipment and electronic devices

In order to fully meet the diverse array of needs and regulations required by their applications, wire harnesses must incorporate dozens of distinct features and capabilities.

We at Precision Manufacturing Company Inc. offer the following capabilities for our wiring harness assembly processes:

- Integration of multiple wire and cable types

- Custom configuration

- Speedy installation time

- Application of multiple interconnects

- 100% fit, form, and function validation

- High-speed automated wire processing

- In-line wire and cable marking

- Harness subassembly prefabrication

- Ultrasonic welding for in-line wire splicing

- Wide range of component options

- Reverse engineering

- Unlimited combinations

Industrial facilities often require unique wire harnesses that conform to industry standards such as UL compliance with fire safety regulations. Infrastructural components (such as public transit controls and bus timers) require fast responsiveness and a high degree of accuracy. At PMCI, our kits and wire harnesses are custom created to meet our clients’ specific needs without delay.

Complying with safety standards is an important aspect of wire harness design and assembly. PMCI’s wire harness facility is ISO 9001:2008 certified for safe wire harness manufacturing. Our operators are certified to IPC WHMA 620 standards, and our soldering operators are certified in J Standard 001. We also build to UL standards.

Start Your Wire Harness Assembly Process Today!

Custom wire harness assemblies are an integral part of reliable residential, commercial, and industrial electronic systems. If you would like to learn more about how we can bring our unique expertise to your next wiring system, contact us today or fill out our online form to request a free quote.

![]() 2149 Valley Street

2149 Valley Street![]() Dayton, OH 45404

Dayton, OH 45404![]() 937.236.2170

937.236.2170![]() 937.236.6023

937.236.6023![]() craigg@precmfgco.com

craigg@precmfgco.com