Precision Manufacturing Company, Inc. (PMCI) is a leading provider of wire harness and cable assemblies. Our advanced equipment, highly trained workforce, and world class customer service ensures high quality products for industries such as heavy equipment, defense, medical, and more.

Wire harnesses are bundles of wires with an exterior sheath that protects cables and wires from external environmental factors and allows electrical contractors and engineers to organize electrical systems. A single wire harness can bundle multiple cables and wires that are already protected by their own exterior coverings. It’s important to understand the differences between the various wire harness covers and wraps to ensure that you choose the right one for your application.

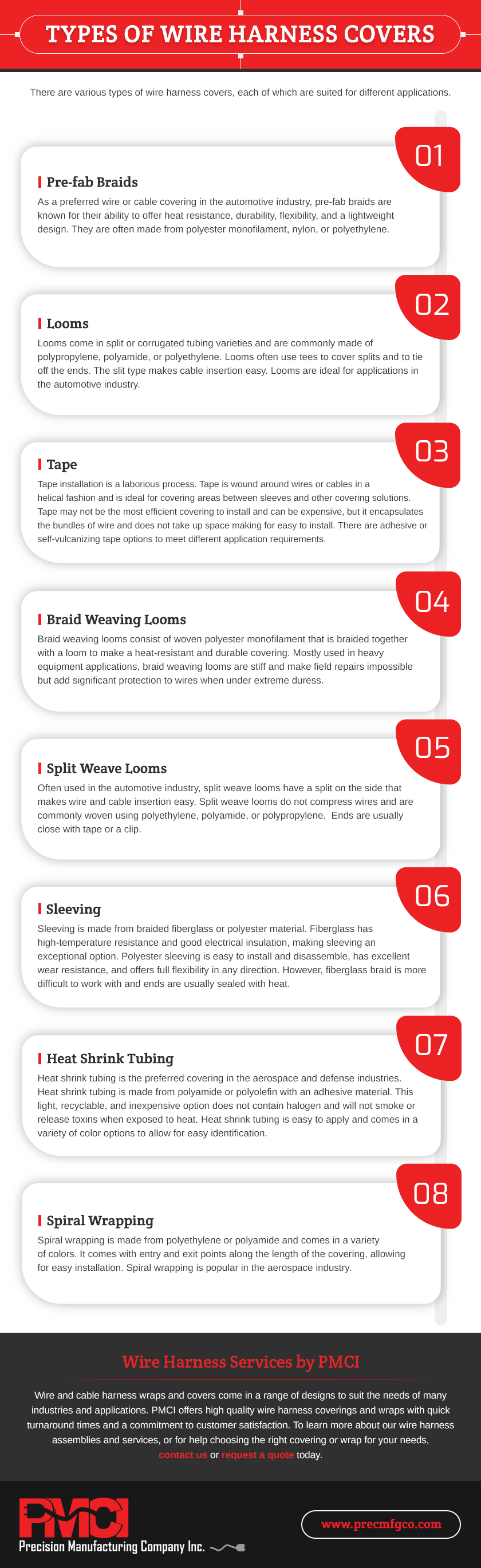

Types of Wire Harness Covers

There are various types of wire harness covers, each of which are suited for different applications.

There are various types of wire harness covers, each of which are suited for different applications.

Pre-fab Braids

As a preferred wire or cable covering in the automotive industry, pre-fab braids are known for their ability to offer heat resistance, durability, flexibility, and a lightweight design. They are often made from polyester monofilament, nylon, or polyethylene.

Looms

Looms come in split or corrugated tubing varieties and are commonly made of polypropylene, polyamide, or polyethylene. Looms often use tees to cover splits and to tie off the ends. The slit type makes cable insertion easy. Looms are ideal for applications in the automotive industry.

Tape

Tape installation is a laborious process. Tape is wound around wires or cables in a helical fashion and is ideal for covering areas between sleeves and other covering solutions. Tape may not be the most efficient covering to install and can be expensive, but it encapsulates the bundles of wire and does not take up space making for easy to install. There are adhesive or self-vulcanizing tape options to meet different application requirements.

Braid Weaving Looms

Braid weaving looms consist of woven polyester monofilament that is braided together with a loom to make a heat-resistant and durable covering. Mostly used in heavy equipment applications, braid weaving looms are stiff and make field repairs impossible but add significant protection to wires when under extreme duress.

Split Weave Looms

Often used in the automotive industry, split weave looms have a split on the side that makes wire and cable insertion easy. Split weave looms do not compress wires and are commonly woven using polyethylene, polyamide, or polypropylene. Ends are usually close with tape or a clip.

Sleeving

Sleeving is made from braided fiberglass or polyester material. Fiberglass has high-temperature resistance and good electrical insulation, making sleeving an exceptional option. Polyester sleeving is easy to install and disassemble, has excellent wear resistance, and offers full flexibility in any direction. However, fiberglass braid is more difficult to work with and ends are usually sealed with heat.

Heat Shrink Tubing

Heat shrink tubing is the preferred covering in the aerospace and defense industries. Heat shrink tubing is made from polyamide or polyolefin with an adhesive material. This light, recyclable, and inexpensive option does not contain halogen and will not smoke or release toxins when exposed to heat. Heat shrink tubing is easy to apply and comes in a variety of color options to allow for easy identification.

Spiral Wrapping

Spiral wrapping is made from polyethylene or polyamide and comes in a variety of colors. It comes with entry and exit points along the length of the covering, allowing for easy installation. Spiral wrapping is popular in the aerospace industry.

At PMCI, we offer a wide variety of wire and cable harness covers and wrapping solutions. Our experts can help you find the best solution for your application or create a custom design that meets your specifications.

Wire Harness Services by PMCI

Wire and cable harness wraps and covers come in a range of designs to suit the needs of many industries and applications. PMCI offers high quality wire harness coverings and wraps with quick turnaround times and a commitment to customer satisfaction. To learn more about our wire harness assemblies and services, or for help choosing the right covering or wrap for your needs, contact us or request a quote today.