Wires and cables play a vital role in electrical and electronic devices and systems. However, they must be built properly to transmit electrical power and signals correctly.

One of the key components that must be considered when designing or selecting a wire or cable is the insulation, which is a non-conductive material that prevents the conducting elements from touching one another and/or protects them from the external environment. It comes in numerous varieties, each of which is suitable for different applications.

Given the broad selection, some people may find it challenging to identify which one is right for their needs. Below, we highlight the types of wire and cable insulation available to help readers determine which one best fits their application requirements and restrictions.

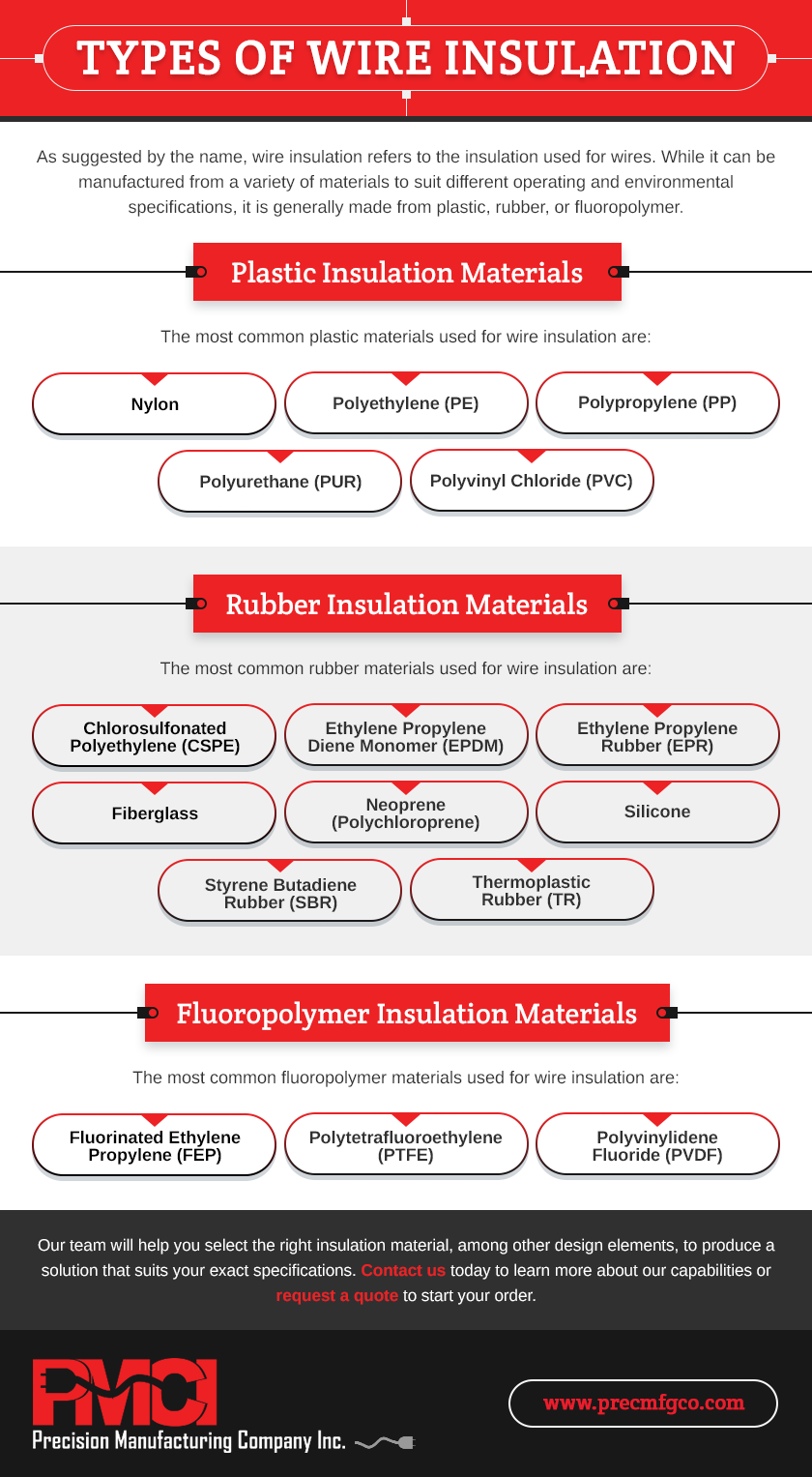

Types of Wire Insulation

As suggested by the name, wire insulation refers to the insulation used for wires. While it can be manufactured from a variety of materials to suit different operating and environmental specifications, it is generally made from plastic, rubber, or fluoropolymer.

Plastic Insulation Materials

The most common plastic materials used for wire insulation are:

- Nylon: This material is normally extruded over softer insulation materials. It creates a flexible and durable jacket that resists damage from abrasion and chemicals. However, its high moisture absorption properties weaken its overall electrical properties.

- Polyethylene (PE): This material is highly versatile. It offers high chemical resistance and low dielectric/capacitance. Chlorinated polyethylene (CPE) serves as a more environmentally friendly option to chlorosulfonated polyethylene (CSPE) and a more flame-resistant alternative to polyvinyl chloride (PVC).

- Polypropylene (PP): This material exhibits similar characteristics to polyethylene but with a wider temperature range. It is typically used for thin-wall primary insulation.

- Polyurethane (PUR): This material is flexible even in low temperatures. It also offers excellent abrasion, chemical, and water resistance. It is normally used for jackets due to its poor electrical properties.

- Polyvinyl Chloride (PVC): This material offers resistance to abrasion, flame, and moisture. It is also compatible with acids, gasoline, ozone, and solvents and suitable for food and medical industry applications. Semi-rigid PVC is generally used as primary insulation that requires abrasion resistance, while plenum PVC is typically used for wires installed in areas with air circulation.

Rubber Insulation Materials

The most common rubber materials used for wire insulation are:

- Chlorosulfonated Polyethylene (CSPE): This material offers chemical and UV resistance. It is suitable for low-voltage insulation. Typical applications include appliance wires and lead wires.

- Ethylene Propylene Diene Monomer (EPDM): This material has high abrasion, heat, ozone, and weather resistance. It is used as an alternative to silicone rubber in certain applications.

- Ethylene Propylene Rubber (EPR): This material has excellent electrical and thermal properties and good chemical and corrosion resistance. It is suitable for high-voltage insulation. Since it is soft and flexible, it must be handled carefully during installation.

- Fiberglass: This material has a continuous working temperature of up to 482° It has good chemical and moisture resistance but poor abrasion resistance.

- Neoprene (Polychloroprene): This material exhibits exceptional abrasion, cut-through, oil, and solvent resistance. It has a wide working temperature range and a long service life.

- Silicone: This material offers excellent flexibility, abrasion and heat resistance, and flame retardance. It can be used for general-purpose and high-temperature insulation, depending on its grade.

- Styrene Butadiene Rubber (SBR): This material serves as an alternative for many natural rubbers. It has similar properties to neoprene.

- Thermoplastic Rubber (TR): This material has excellent aging, heat, and weather resistance but limited cut-through resistance. It is typically used for applications that require high processing speeds and wide operating temperature ranges.

Fluoropolymer Insulation Materials

The most common fluoropolymer materials used for wire insulation are:

- Fluorinated Ethylene Propylene (FEP): This material has excellent resistance to flames. It can be foamed to optimize data transmission across cables and wires.

- Polytetrafluoroethylene (PTFE): This material provides consistent performance. It offers a broad temperature range, high flexibility, and resistance to chemicals, oils, and water.

- Polyvinylidene Fluoride (PVDF): This material is highly flexible, lightweight, and low cost. It has resistance to abrasion, chemicals, fire, heat, and weather.

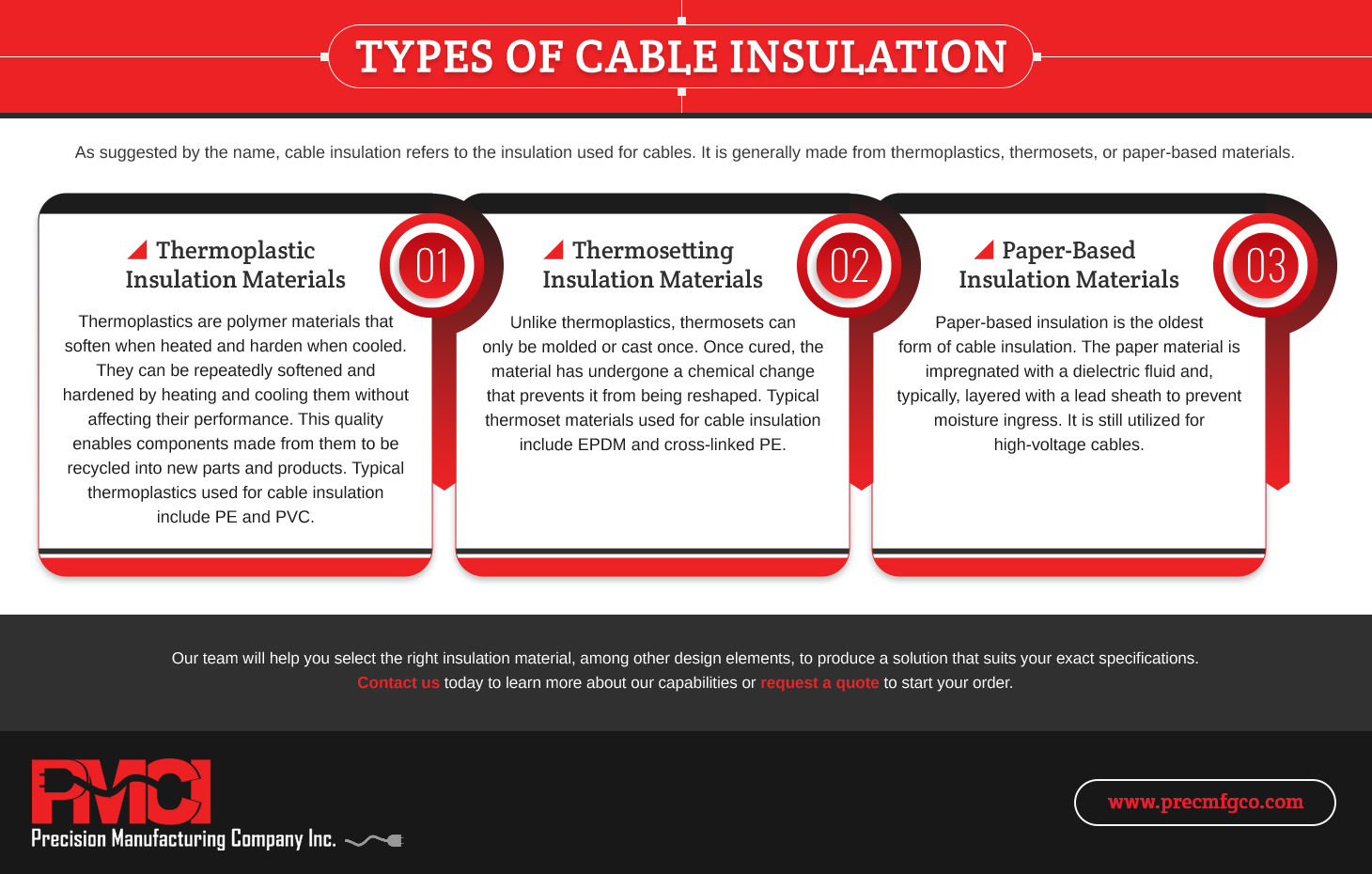

Types of Cable Insulation

As suggested by the name, cable insulation refers to the insulation used for cables. It is generally made from thermoplastics, thermosets, or paper-based materials.

Thermoplastic Insulation Materials

Thermoplastics are polymer materials that soften when heated and harden when cooled. They can be repeatedly softened and hardened by heating and cooling them without affecting their performance. This quality enables components made from them to be recycled into new parts and products. Typical thermoplastics used for cable insulation include PE and PVC.

Thermosetting Insulation Materials

Unlike thermoplastics, thermosets can only be molded or cast once. Once cured, the material has undergone a chemical change that prevents it from being reshaped. Typical thermoset materials used for cable insulation include EPDM and cross-linked PE.

Paper-Based Insulation Materials

Paper-based insulation is the oldest form of cable insulation. The paper material is impregnated with a dielectric fluid and, typically, layered with a lead sheath to prevent moisture ingress. It is still utilized for high-voltage cables.

Partner With PCMI for Your Insulated Wire and Cable Needs!

If you need assistance choosing an insulation material for your wires and cables, the experts at Precision Mfg. Co., Inc. are here to help! Armed with over 50 years of experience handling wires and cables, we have what it takes to help with any wire or cable need. Our team will help you select the right insulation material, among other design elements, to produce a solution that suits your exact specifications. Contact us today to learn more about our capabilities or request a quote to start your order.

Recent Comments