When the time comes for manufacturers of electrical products to select a cable to connect electrical components, the decision ultimately comes down to either a shielded or unshielded cable. Cost, flexibility, and protection against interference—dictated by the cable’s environment—will all help guide you to the answer.

Shielded cables are more expensive and unwieldy than unshielded cables but offer increased protection against electromagnetic interference (EMI) that can slow down or disable electrical systems. Unshielded cables are easier to install and maintain but are not protected from EMI.

Cables in clean, indoor, and dry environments may be unshielded, while environments that are harsh, outdoor, or moist are more likely to require shielded cables.

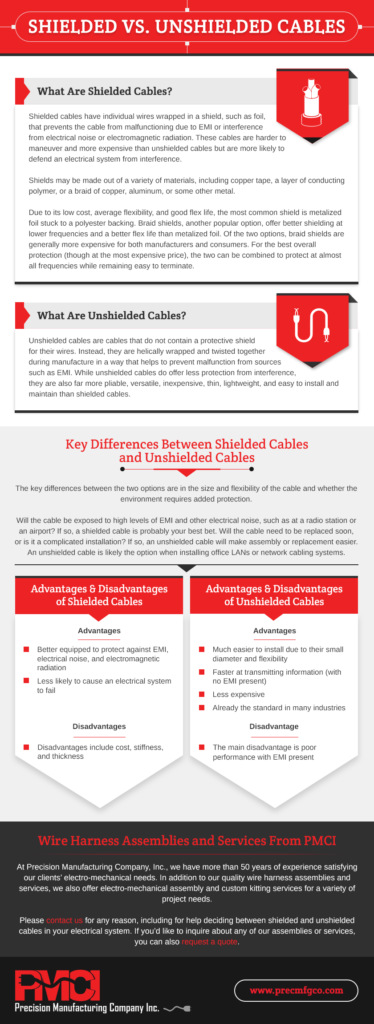

What Are Shielded Cables?

Shielded cables have individual wires wrapped in a shield, such as foil, that prevents the cable from malfunctioning due to EMI or interference from electrical noise or electromagnetic radiation. These cables are harder to maneuver and more expensive than unshielded cables but are more likely to defend an electrical system from interference.

Shields may be made out of a variety of materials, including copper tape, a layer of conducting polymer, or a braid of copper, aluminum, or some other metal.

Due to its low cost, average flexibility, and good flex life, the most common shield is metalized foil stuck to a polyester backing. Braid shields, another popular option, offer better shielding at lower frequencies and a better flex life than metalized foil. Of the two options, braid shields are generally more expensive for both manufacturers and consumers. For the best overall protection (though at the most expensive price), the two can be combined to protect at almost all frequencies while remaining easy to terminate.

What Are Unshielded Cables?

Unshielded cables are cables that do not contain a protective shield for their wires. Instead, they are helically wrapped and twisted together during manufacture in a way that helps to prevent malfunction from sources such as EMI. While unshielded cables do offer less protection from interference, they are also far more pliable, versatile, inexpensive, thin, lightweight, and easy to install and maintain than shielded cables.

Key Differences Between Shielded Cables and Unshielded Cables

Key Differences Between Shielded Cables and Unshielded Cables

The key differences between the two options are in the size and flexibility of the cable and whether the environment requires added protection.

Will the cable be exposed to high levels of EMI and other electrical noise, such as at a radio station or an airport? If so, a shielded cable is probably your best bet. Will the cable need to be replaced soon, or is it a complicated installation? If so, an unshielded cable will make assembly or replacement easier. An unshielded cable is likely the option when installing office LANs or network cabling systems.

Advantages of Shielded Cables

Shielded cables are:

- Better equipped to protect against EMI, electrical noise, and electromagnetic radiation

- Less likely to cause an electrical system to fail

Disadvantages include cost, stiffness, and thickness.

Advantages of Unshielded Cables:

Unshielded cables are:

- Much easier to install due to their small diameter and flexibility

- Faster at transmitting information (with no EMI present)

- Less expensive

- Already the standard in many industries

The main disadvantage is poor performance with EMI present.

Wire Harness Assemblies and Services From PMCI

At Precision Manufacturing Company, Inc., we have more than 50 years of experience satisfying our clients’ electro-mechanical needs. In addition to our quality wire harness assemblies and services, we also offer electro-mechanical assembly and custom kitting services for a variety of project needs.

Please contact us for any reason, including for help deciding between shielded and unshielded cables in your electrical system. If you’d like to inquire about any of our assemblies or services, you can also request a quote.

Recent Comments